From what I remember when I was designing PID, the proportional gain was usually less than 0.01 for me.(That being said it depends on the application) I don't know about arduino auto-tuning but you can tune your variables using matlab, transfer function of the system or using Nyquist plot. We can express PID control mathematically with the following equation. P, I, and D are represented by the three terms that add together here. K p, K i, and K d are constants that tune how the system reacts to each factor: We can also replace K i and K d with 1/T i and T d, respectively. This change gives the equation a better.

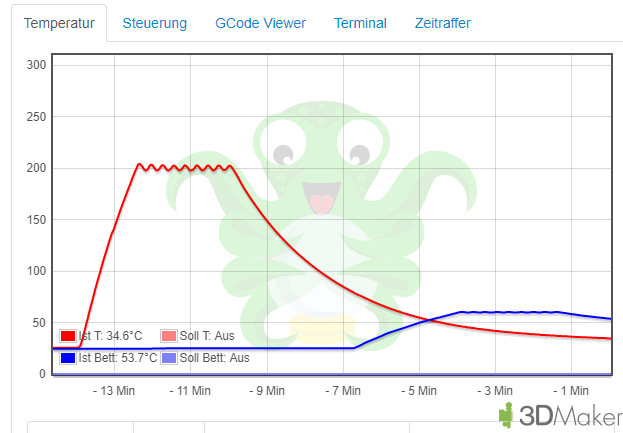

Temperature management by your 3D printer is often made using PID controller.

29 thoughts on “ PID Control With Arduino ”. And I just read the article. Next he needs an auto-tune function to calculate the initial P,I,D values. Look up “PID tuning”. Arduino IDE in the Cloud. Codebender includes a Arduino web editor so you can code, store and manage your Arduino sketches on the cloud, and even compile and flash them. Library: PIDAutoTunev0.

Arduino Pid Motor

Requirements:

- Pronterface (Windows, Mac)

- Arduino IDE (optional)

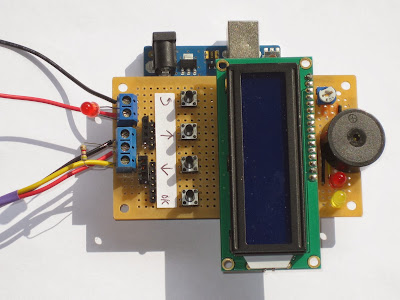

- 3D printer with active PID for the target heating element

Pronterface installation:

Pronterface is a cross platform host software for your 3D printer. It allows to send commands to your 3D printers in a simple way.

This application is stand alone and doesn’t require any installation

In order to be able to connect to your 3D printer you need to install the serial drivers of your electronic board.

Auto Tuning Pid Arduino Esp8266

Scalar 3D printers are using arduino MEGA 2560, so you only need to install Arduino IDE in order for the proper drivers to be installed.

Once you have downloaded the proper version of Pronterface , you will need to unzip it’s content in a folder.

Inside you should have the following file tree.

At this stage you will need to connect your 3D printer using a USB cable.

Once the drivers are installed, your OS will assign a specific COM port to your 3D printer.

Now you can launch « pronterface.exe »

The following window will appear

Warning!

Depending on your OS you might need the proper user rights in order to acces COM port

Consider running your application as Administrator

Once the drivers for the seria COM port are installed your 3D printer COM port should be visible inside the drop down list of Pronterface (1)

- You should see the proper COM port asigned to your Arduino MEGA inside this drop down list

- Select the baud rate to 115200Bps (at least for Scalar 3D printers)

- Push the Connect button.

Once connected you should have a lot of information coming into the console window on the left side of the application.

PID Auto tuning

PID auto tune has to be made when your heating element is at Ambient temperature. Otherwise you will get wrong parameters!

In the bottom part of the console view, you have a text box where you can enter single commands for your 3D printers,

Hot end PID

Iin order to perform the PID tuning of your hot end you will need to send the following command :

E0 is for Extruder 0 (your hot end) , S210 is the target temperature (here 201°C) and C8 is the amount of iterations to perform , Here 8. The higher the number the more accurate your PID will be.

you will need to wait a few minutes in order for the algorithm to converge to a set a values.

here we found out

your PID values will be different from the one here

Take theses PID values into account

Use the following command in order for your controller to take the Ki, Kp, and Kd values into account

Make sure you have updated the command with the PID values that you found!

Save your settings into the EEPROM

M500 allows to save your settings into the controller EEPRO

Heat bed PID Command

Take the Heatbed PID values into account

Save into EEPROM

(source http://reprap.org/wiki/PID_Tuning )

- http://arduino.cc/ (consulted in January 2014)

- Margolis, M.: Arduino Cookbook. O’Reilly (2011)Google Scholar

- Ästrom, K.J., Hägglund, T.: Automatic Tuning of PID Controllers. Instrument Society of America (1988)Google Scholar

- Ästrom, K.J., Hägglund, T.: PID Controllers: Theory, Design and Tuning, 2nd edn. Instrument Society of America (1995)Google Scholar

- Ästrom, K.J., Wittenmark, B.: Adaptive Control, 2nd edn. Addison-Wesley (1995)Google Scholar

- Chen, C.-T.: Analog and Digital Control System Design - Transfer-Function, State-Space and Algebraic Methods. Saunders (1993)Google Scholar

- Nise, N.: Control Systems Engineering, 3rd edn. Wiley (2000)Google Scholar

- Hägglund, T., Ästrom, K.J.: Method and an apparatus in tuning a PID-regulator, US Patent 4549123 (1983)Google Scholar

- Phillips, C.L., Harbor, R.D.: Feedback Control Systems, 2nd edn. Prentice-Hall (1991)Google Scholar

- Slotine, J.E., Li, W.: Applied Nonlinear Control. Prentice-Hall (1991)Google Scholar

- Soltesz, K., Hägglund, T., Ästrom, K.J.: Transfer Function Parameter Identification by Modified Relay Feedback. In: 2010 American Control Conference, Baltimore, Maryland, USA (2010)Google Scholar

- Soltesz, K., Hägglund, T.: Extending the Relay Feedback Experiment. In: 18th IFAC World Congress, Milano, Italy (2011)Google Scholar